Description

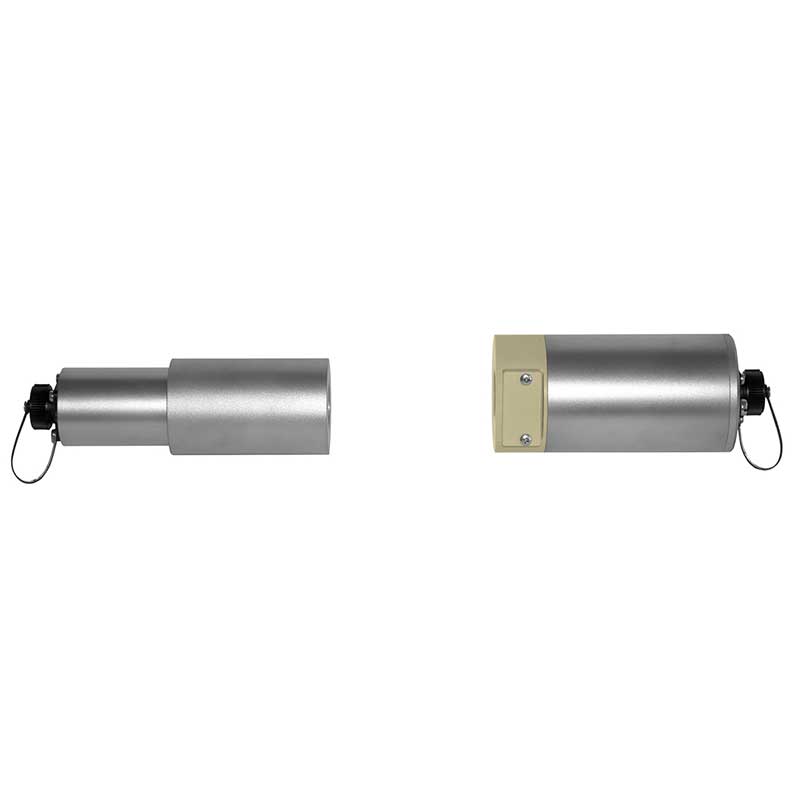

Dual Channel VIS/NIR Absorption Sensor

The AF26 is a high precision dual channel color sensor for inline operation; the secondary wavelength is designed to compensate the desired light absorbance measurement from any undesired light scattering influence, such as suspended solids, gas bubbles, immiscible fluids or window fouling. The AF26 sensor’s output can be correlated to almost any color scale including APHA and Hazen.

Used For

- Color scales:

- APHA / HAZEN / Pt/Co color

- AOCS (Method Cc 13b-45) color

- ASTM (D1500) color

- EBC color

- ASBC color

- Gardner (ASTM D1544) color

- ICUMSA color

- KLETT color

- Reference Base Unit (RBU, color)

- Saybolt (ASTM D 156, D 6045) color

- Concentration control of

- chlorine and chlorine dioxide (gas and liquid)

- of metal ions (Iron, Chromium, Copper, Nickel, Cobalt, Manganese, etc. ) in Plating industry

- Drinking water treatment (APHA color)

- Colored waste water monitoring (e.g., Textile industry)

Typical Applications

The AF26 is a high precision dual channel sensor which is designed for inline operation. The dual channel AF26 sensor provides accurate absorption measurements with remarkable repeatability, linearity and resolution. The AF26 sensor’s output can be correlated to almost any color scale including APHA and Hazen. Selected combinations of optical filters make it possible to focus on specific wavelengths ensuring suitable adaptation to the application. Typically, one of the two measured wavelengths is used as a reference channel, where it can be used to prevent the influence of particulate, gas bubbles and lamp aging. Additionally, NIST-traceable calibration accessories provide absolute measurement confidence.

| AF26 | ||

|---|---|---|

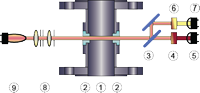

| Schematic |

|

|

| Measurement | ||

| Measurement principle | 2- Channel Absorption of light | |

| Measurement wavelength(s) | 385/430, 385/550, 385/620, 400/550, 400/620, 420/700, 430/525, 430/620, 430/700, 460/620, 470/620, 470/700, 525/620, 525/700, 550/800, 620/800, 660/750, 670/550, 670/750, 1000/800 nm, others on request | |

| Detector(s) | 2 silicon photodiodes (hermetically sealed) | |

| Measuring Range | any measuring range between

0 – 0.05 to 3 CU (dependent on filter used) (contact product specialist for application specific ranges) |

|

| Optical path length | 1 – 1000 mm | |

| Calibration | CU (concentration units) application specific calibration | |

| Light source | special incandescent tungsten lamp 5.0 V DC, 970 mA

typical life span: 3 to 5 years (25,000 to 40,000 hours) |

|

| Resolution | < ± 0.05 % of respective measuring range | |

| Repeatability | < ± 0.5 % of respective measuring range | |

| Linearity | < ± 1 % of respective measuring range (specific to application) | |

| Protection | all optical parts have an IP rating of IP65 or higher | |

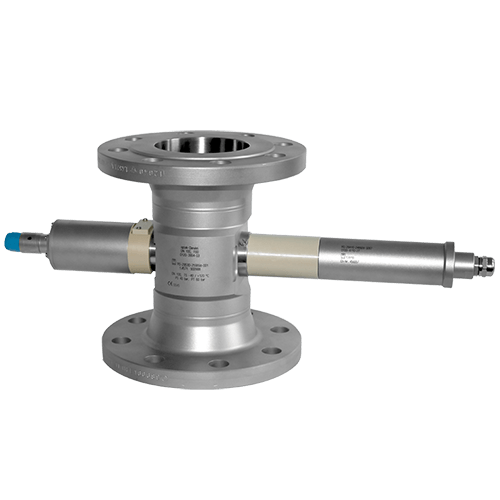

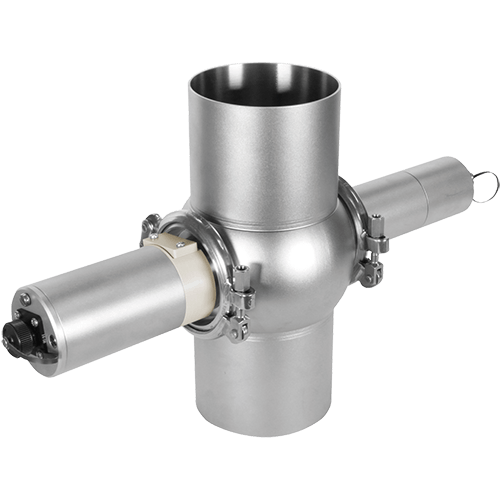

| Sensor Body | ||

| Material | Stainless steel 1.4435 (SS 316L), 1.4539, 1.4571 (SS 316Ti), 1.4462, Titanium 3.7035 (Grade 2), Hastelloy 2.4602 (C22), Plastic TFM4215, PVC, … others on request | |

| Line size | 1/8 in. to 6 in. (DN 6 to DN 150), … others on request | |

| Process connection | Flanges (ASME, DIN, JIS), Clamps (TC, ISO, DIN), Female Threads (NPT, DIN), Sanitary Threads (DIN 11851), Tube Ends (DIN, ISO, OD), Varivent, … others on request | |

| Process pressure | 10 mbar to 100 bar (0.15 psi to 1450 psi) – higher on request depending on process connection, materials and design | |

| Windows | 1-Pyrex®, 2-Sapphire, 3-Sapphire Biotech | |

| Window gaskets | Silicone (FDA), Viton® (FDA), EPDM (FDA / USP Class VI), Kalrez® 4079, … others on request | |

| Temperature Ratings | ||

| Process temperature | permanent: 0 – 120 °C ( 32 – 248 °F)

peak 15 min/day: 0 – 150 °C ( 32 – 302 °F) |

|

| Process temperature OPTION HT |

permanent: -30 – 240 °C (-22 – 464 °F)

peak 15 min/day: -30 – 260 °C (-22 – 500 °F) |

|

| Process temperature OPTION EX |

permanent: -30 – 120 °C (-22 – 248 °F)

peak 15 min/day: -30 – 150 °C (-22 – 302 °F) |

|

| Process temperature OPTION EX-HT |

permanent: -30 – 240 °C (-22 – 464 °F)

peak 15 min/day: -30 – 260 °C (-22 – 500 °F) |

|

| Ambient temperature | permanent: 0 – 40 °C ( 32 – 104 °F)

operation: -30 – 40 °C (-22 – 104 °F) with options HT / EX / EX-HT transport: -20 – 70 °C ( -4 – 158 °F) |

|

| Explosion Proof | ||

| Ex-proof | none | |

| Ex-proof OPTION EX (EN-D) |

Sensor assembly in ex-proof version accor. ATEX (EN-D) | |

| Ex-proof OPTION EX (FM-D) |

Sensor assembly in ex-proof version accor. FM (FM-D) | |

| Calibration | ||

| Calibration adapter | none | |

| Calibration adapter VB | Filter adapter FH03 for calibration filter used for sensor verification | |

| Pressure and temperature ratings specified herein may be subject to limitations – see instruction manual. The appropriate choice of material for all wetted parts is the sole responsibility of the user. Data given are subject to changes without prior notice. | ||

Product Variants

AF26-EX-HT-VB

AF26-EX-VB

AF26-VB-PV

Process temperature OPTION HT

permanent: -30 – 240 °C (-22 – 464 °F)

peak 15 min/day: -30 – 260 °C (-22 – 500 °F)

Ex-proof OPTION EX (EN-D)

Sensor assembly in ex-proof version accor. ATEX (EN-D)

Ex-proof OPTION EX (FM-D)

Sensor assembly in ex-proof version accor. FM (FM-D)