Description

Single Channel Color Sensor

AF56-F is a high quality sensor for direct installation into pipelines measuring visible (VIS) light absorption of various liquid samples at a specific wavelength of 430 nm. The optical path length (OPL) can be individually configured to meet the process control requirements.

Used For

- Color scale:

- CU (concentration units)

- Color monitoring

- of CIP processes

- for interface detection in beverage production

The AF56-F is a precision color sensor which is designed for inline operation. Using light in the visible range (VIS) at 430 nm the AF56-F is used to measure color or color changes. A light reduction based on an increased intensity of the color is precisely detected.

| AF56-F | ||

|---|---|---|

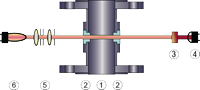

| Schematic |

|

|

| Measurement | ||

| Measurement principle | 1- Channel Absorption of light | |

| Measurement wavelength(s) | AF56-F:430 nm | |

| Detector(s) | 1 silicon photodiode (hermetically sealed) | |

| Measuring Range | any measuring range between

AF56-F:0 – 0.5 to 2 CU |

|

| Optical path length | 1 – 200mm | |

| Calibration | Abs.: CU (concentration units) application specific calibration | |

| Light source | special incandescent tungsten lamp 5.0 V DC, 970 mA

typical life span: 3 to 5 years (25,000 to 40,000 hours) |

|

| Resolution | < ± 0.5 % of respective measuring range | |

| Repeatability | < ± 1.0 % of respective measuring range | |

| Linearity | < ± 2 % of respective measuring range (specific to application) | |

| Protection | all optical parts have an IP rating of IP65 or higher | |

| Sensor Body | ||

| Material | Stainless steel 1.4435 (SS 316L), 1.4539, 1.4571 (SS 316Ti), 1.4462, Titanium 3.7035 (Grade 2), Hastelloy 2.4602 (C22), Plastic TFM4215, PVC, … others on request | |

| Line size | 1/8 in. to 6 in. (DN 6 to DN 150), … others on request | |

| Process connection | Flanges (ASME, DIN, JIS), Clamps (TC, ISO, DIN), Female Threads (NPT, DIN), Sanitary Threads (DIN 11851), Tube Ends (DIN, ISO, OD), Varivent, … others on request | |

| Process pressure | 10 mbar to 100 bar (0.15 psi to 1450 psi) – higher on request depending on process connection, materials and design | |

| Windows | 1-Pyrex®, 2-Sapphire, 3-Sapphire Biotech | |

| Window gaskets | Silicone (FDA), Viton® (FDA), EPDM (FDA / USP Class VI), Kalrez® 4079, … others on request | |

| Temperature Ratings | ||

| Process temperature | permanent:0 – 100 °C (32 – 212 °F)

peak (15 min/day):0 – 120 °C (32 – 248 °F) |

|

| Process Temperature OPTION SF |

permanent:0 – 60 °C (32 – 140 °F)

peak (15 min/day):0 – 80 °C (32 – 176 °F) |

|

| Ambient temperature | operation:0 – 40 °C (32 – 104 °F)

transport:-20 – 70 °C ( -4 – 158 °F) |

|

| Pressure and temperature ratings specified herein may be subject to limitations – see instruction manual. The appropriate choice of material for all wetted parts is the sole responsibility of the user. Data given are subject to changes without prior notice. | ||