Description

Single Channel Turbidity Probe

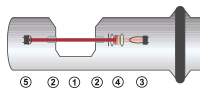

AS56-N is a probe for direct installation into pipelines and vessels measuring NIR light absorption (Turbidity or Solids Concentration) in various liquid flow streams. Two optical path length choices allow the measurement range to meet the process control requirements.

Used For

- Turbidity scale:

- CU (concentration units)

- Turbidity based

- phase separation control (Product / Water)

- inlet separator control

- yeast dosing / Brinks / harvesting

- control of CIP processes

- Wastewater solids

The AS56-N is a precision absorption probe, which is designed for direct installation into pipelines and provides accurate concentration measurements with remarkable repeatability, linearity and resolution. It is typically used in food and beverage applications to allow cost-effective measurements. The AS56-N uses light from 730-970 nm to measure solids concentration independent from color or color changes (e.g., yeast concentration in beer during tank draining). It’s lowered power design allows for up to four AS56 series sensors to be multiplexed to one C4000 converter / transmitter.

| AS56-N | ||

|---|---|---|

| Schematic |

No window gaskets used |

|

| Measurement | ||

| Measurement principle | 1- Channel Absorption of light | |

| Measurement wavelength(s) | AS56-N:730 – 970 nm | |

| Detector(s) | 1 silicon photodiode (hermetically sealed) | |

| Measuring Range | AS56-N:

any measuring range between 0 – 0.05 to 4 CU |

|

| Optical path length | 5 or 10 mm | |

| Calibration | CU (concentration units) application specific calibration | |

| Light source | special incandescent tungsten lamp 5.0 V DC, 450 mA

typical life span: 3 to 5 years (25,000 to 40,000 hours) |

|

| Resolution | < ± 0.5 % of respective measuring range | |

| Repeatability | < ± 1.0 % of respective measuring range | |

| Linearity | < ± 2 % of respective measuring range (specific to application) | |

| Protection | all optical parts have an IP rating of IP65 or higher | |

| Process Adaption | ||

| Material | wetted parts: stainless steel 1.4435 (SS 316 L)

surface: electro-polished Ra < 0,8 μm housing: stainless steel 1.4571 (SS 316 Ti) |

|

| Port connection | thread G1-1/4 in., ISO 228/1 for port AS25 (similar Ingold-port)

diameter: 25 mm ( D= 25 H7) O-ring groove for 30 mm and for 60 mm port length |

|

| Port gasket | O-ring 18.64 x 3.53 mm EPDM (FDA / USP Class VI) | |

| Insertion depth | 35 mm (1.38 in.) + OPL at a port length of 60 mm (2.36 in.) | |

| Process pressure | 10 mbar to 10 bar (0.15 psi to 145 psi) | |

| Windows | Sapphire (seal-less) | |

| Installation accessories |

|

|

| Temperature Ratings | ||

| Process temperature | permanent:0 – 90 °C (32 – 194 °F)

peak 60 min/day:0 – 100 °C (32 – 212 °F) |

|

| Ambient temperature | operation:0 – 40 °C (32 – 104 °F)

transport:-20 – 70 °C ( -4 – 158 °F) |

|

| Pressure and temperature ratings specified herein may be subject to limitations – see instruction manual. The appropriate choice of material for all wetted parts is the sole responsibility of the user. Data given are subject to changes without prior notice. | ||