Description

Triple Beam Scattered Light Benchtop Turbidity Analyzer

Quick turbidity analysis in bottles, e.g., in beer production, make the DT9011 an ideal measuring device for Quality Assurance and Control, even accepting cuvettes for scattered light analysis. Final product control in bottles save time, reduces handing steps and with the integrated sample turning function, variations of the bottles can be compensated.

Used For

- Nephelometric turbidity measurement at 0° (reference), 11°, 90°

- Turbidity scales:

- CU (concentration units)

- ppm (DE)

- FTU

- NTU

- FAU

- EBC (ASBC)

- Helms

- Typical Uses

- Direct measurements in bottles or cuvettes

- Finished Product Quality Control and Assessment

- Process Analyzer Backup – Verification

- Stable Cloud Assessments

- Filtration Predictability

- Shelf Stability Analysis

Typical Applications

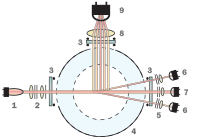

The DT9011 is an “In the Bottle” Turbidimeter, which also accepts cuvettes for upstream process sampling. It provides both an 11° Forward Scatter Measurement for direct assessment of Turbidity content as well as a 90° Side Scatter Measurement for Clarity / Haze assessment. MEBAK compliant wavelength bandwidth protects light sensitive products, compensates for product / vessel color and eliminates any particle size sensitivity.

The suppressed stray light, Triple Beam – Ratio measurement design compensates for bottle and product color as well as lamp aging. Factory zero and calibration stability means multiple analyzers will always provide comparable results, which are also comparable to the optek DTF16 inline Turbidity Sensor. Calibrations or zero point settings in the field are not necessary. User selectable units scales provide ultimate flexibility across broad product ranges. Transferable data allows it to be tied in directly to your DCS (distributed control system), via an RS232 serial port.

| DT9011 | ||

|---|---|---|

| Schematic |

|

|

| Measurement | ||

| Measurement principle | 1- Channel Absorption of light and 2-Channel Scattering of light (11° and 90°) | |

| Measurement wavelength(s) | 590 nm – 1100 nm | |

| Detector(s) | 1 silicon photodiode (hermetically sealed) (Abs.)

1 silicon photodiode (hermetically sealed) (90°) 8 silicon photodiodes (hermetically sealed) (11°) |

|

| Measuring Range | Bottles

any measuring range between

Cuvettes any measuring range between

|

|

| Calibration | factory calibration (11° and 90°)

user calibration possible, at any time reversible to factory calibration comparison between factory settings and user settings possible |

|

| Light source | special halogen lamp 5.0 V DC, 970 mA

typical life span: 1.5 to 3 years (12,500 to 25,000 hours) |

|

| Resolution | 0 – 1 EBC to 0 – 4 FTU:

< ± 1 % of respective measuring range 0 – 100 EBC or 0 – 400 FTU: < ± 0.05 % of respective measuring range |

|

| Repeatability | < ± 1.0 % in cuvette | |

| Linearity | < ± 1.0 % in cuvette | |

| Protection | table case front IP40 | |

| System | ||

| Material | housing:stainless steel 1.4301 (SS304)

dimensions:W 381 mm (15 in.) H 394 mm (15.5 in.) D 445 mm (17.5 in.) measurement chamber:POM C tubing:PA, PVC fittings:stainles steel, brass |

|

| Water bath | overflow drain valve (flow regulation)

sensor for minimum water level volume:600 ml (20 fl oz) flow:5 to 15 l/h with circulation |

|

| Rotation system | standard | |

| Display | LCD graphic display black on white (240 x 128 pixel), LED background illuminated | |

| Operation | 18-button keyboard | |

| System clock | accuracy approx. 1 minute/month (battery life approx. 15 years) | |

| LED | 1 LED (green):power on

1 LED (red-flashing):system failure / lamp failure 2 LEDs (yellow):alarm I, II |

|

| Serial communication | RS232 bi directional interface on the back ( with software package optek PC-transfer)

upload /download of configuration, download of data logger content |

|

| Power supply | 115 / 230 V AC, selectable (93.5 – 132 / 187 – 264 V AC, 47 – 64 Hz)

consider an external release device power consumption:< 50 VA |

|

| Windows | borosilicate glass | |

| Gaskets | buna, Viton® | |

| Cuvettes | diameter:Ø 58.0 mm to Ø 72.5 mm (2.28 in to 2.85 in.)

wall thickness:minimum 2 mm (0.08 in.) height:140 – 280 mm (5.5 – 11.0 in.) |

|

| Bottles | diameter:Ø 58.0 – 72.5 mm (2.28 – 2.85 in.)

height:140 – 280 mm (5.5 – 11.0 in.) color:green, brown, clear |

|

| Bottle insert | adapter 61 mm (2.40 in.):bottles Ø 58.0 – 60.5 mm (2.28 – 2.38 in.)

adapter 64 mm (2.52 in.):bottles Ø 60.5 – 63.5 mm (2.38 – 2.50 in.) adapter 67 mm (2.64 in.):bottles Ø 63.5 – 66.5 mm (2.50 – 2.62 in.) adapter 70 mm (2.76 in.):bottles Ø 66.5 – 69.5 mm (2.62 – 2.74 in.) without adapter:bottles Ø 69.5 – 72.5 mm (2.74 – 2.85 in.) |

|

| Temperature Ratings | ||

| Water bath remperature | 10° C to 40 °C (50° F to 104 °F) | |

| Ambient temperature | operation:0 – 40 °C (32 – 104 °F)

transport:-20 – 70 °C ( -4 – 158 °F) |

|

| Pressure and temperature ratings specified herein may be subject to limitations – see instruction manual. The appropriate choice of material for all wetted parts is the sole responsibility of the user. Data given are subject to changes without prior notice. | ||