Description

High performance 3 channel nephelometric turbidity sensor

The DTF16 is a high 3 channel turbidity sensor for installation into pipelines, measuring turbidity at two angles of scattered light and a direct reference channel in various liquid flow streams.

Used For

- High precision control of turbidity with compensation of colored products

- Turbidity scales:

- CU (concentration units)

- ppm (DE)

- FTU

- NTU

- FAU

- Turbidity based

- separator control

- beer filtration: quality and clarity at each step

- Pectin filtration

- Turbidity measurement angles: 0°, 11°, 90°

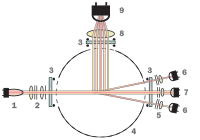

The optek DTF16 is an advanced function inline turbidity sensor for filtration control, release line turbidity and real-time quality control. It provides both an 11° Forward Scatter Measurement for highly sensitive detection of particles as well as a 90° side scatter measurement for standardized clarity / haze assessment. The stray light suppressed, triple beam – ratio measurement design compensates for product color as well as lamp aging. Factory zero and calibration stability ensure that multiple analyzers will always provide comparable results, which are also comparable to our DT9011 bench-top turbidity analyzer. Calibrations or zero point settings in the field are not necessary.

| DTF16 | ||

|---|---|---|

| Schematic |

|

|

| Measurement | ||

| Measurement principle | 1- Channel Absorption of light and 2-Channel Scattering of light (11° and 90°) | |

| Measurement wavelength(s) | 590 nm – 1100 nm | |

| Detector(s) | 1 silicon photodiode (hermetically sealed) (Abs.)

1 silicon photodiode (hermetically sealed) (90°) 8 silicon photodiodes (hermetically sealed) (11°) |

|

| Measuring range NIR-Absorption | any measuring range between

|

|

| Measuring range Scattered Light (11°) | any measuring range between

|

|

| Measuring range Scattered Light (90°) | any measuring range between

|

|

| Optical path length | 80 mm standard | |

| Calibration | factory calibration (11° and 90°)

0 – 25 EBC / 0 – 100 FTU in standard sensor body (OPL = 80 mm) |

|

| Light source | special halogen lamp 5.0 V DC, 970 mA

typical life span: 1.5 to 3 years (12,500 to 25,000 hours) |

|

| Resolution | < ± 0.05 % of respective measuring range | |

| Repeatability | < ± 0.3 % of respective measuring range | |

| Linearity | < ± 0.5 % of respective measuring range

(with standard solution, specific to application) |

|

| Protection | all optical parts have an IP rating of IP65 or higher | |

| Sensor Body | ||

| Material | Stainless steel 1.4435 (SS 316L), Plastic TFM4215, others on request | |

| Line size | 1.5 in. to 6 in. (DN 40 to DN 150), others on request | |

| Process connection | butt weld tube ends:DIN 11850, ISO 1127, IPS (Schedule 5), OD (BS 4825-1), others on request (e.g. Flange (DIN, ASME), Tri-Clamp) | |

| Process pressure | 10 mbar to 20 bar (0.15 psi to 280 psi) | |

| Windows | 3-Sapphire Biotech (type 3A) | |

| Window gaskets | EPDM (FDA / USP Class VI), others on request | |

| Temperature Ratings | ||

| Process temperature | permanent: 0 – 120 °C ( 32 – 248 °F)

peak 15 min/day: 0 – 150 °C ( 32 – 302 °F) |

|

| Ambient temperature | operation:0 – 40 °C (32 – 104 °F)

transport:-20 – 70 °C ( -4 – 158 °F) |

|

| Pressure and temperature ratings specified herein may be subject to limitations – see instruction manual. The appropriate choice of material for all wetted parts is the sole responsibility of the user. Data given are subject to changes without prior notice. | ||