Description

Dual Channel Turbidity Sensor

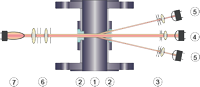

The TF56-N sensor is an inline real-time device designed to measure light absorbance at 11° caused by interaction with process turbidity. As an NIR light beam is passed through a dynamic process stream, the sensor simultaneously measures the amount of light scattered at 11° and the remaining amount of un-scattered light at 0°.

Used For

- Turbidity scales:

- ppm (DE)

- FTU (ISO)

- EBC

- Turbidity monitoring

- in filter control

- of condensate

- for separator control (food & beverage)

- Lauter tun / mash filter control

- Turbidity measurement angle 0°, 11°

The TF56-N is a precision scattered light turbidity sensor, which is designed for inline operation. Light scattered from particles (trace suspended solids, undissolved liquids or gas bubbles) in the medium is detected by four hermetically sealed silicon photodiodes at an angle of 11°. At the same time, the direct light is detected by a reference photodiode. This unique dual channel design compensates for disturbances of the carrier medium. The sensor can be calibrated in ppm (DE), EBC or FTU and measures extremely low particle sizes and concentrations.

| TF56-N | ||

|---|---|---|

| Schematic |

|

|

| Measurement | ||

| Measurement principle | 2- Channel Scattering of light (11°) | |

| Measurement wavelength(s) | 730 nm – 970 nm | |

| Detector(s) | 1 silicon photodiode (hermetically sealed)(Abs.)

4 silicon photodiodes (hermetically sealed) (11°) |

|

| Measuring Range | any measuring range between

0 – 25 to 500 ppm (DE) 0 – 10 to 200 FTU 0 – 2.5 to 50 EBC |

|

| Optical path length | 40 mm standard

(50 – 60 mm with reduced accuracy) |

|

| Calibration | basic calibration 11°: in ppm (DE) / FTU / EBC | |

| Light source | special incandescent tungsten lamp 5.0 V DC, 970 mA

typical life span: 3 to 5 years (25,000 to 40,000 hours) |

|

| Resolution | < ± 0.5 % of respective measuring range | |

| Repeatability | < ± 1.0 % of respective measuring range | |

| Linearity | < ± 2 % of respective measuring range (specific to application) | |

| Protection | all optical parts have an IP rating of IP65 or higher | |

| Sensor Body | ||

| Material | Stainless steel 1.4435 (SS 316L), 1.4539, 1.4571 (SS 316Ti), 1.4462, Titanium 3.7035 (Grade 2), Hastelloy 2.4602 (C22), Plastic TFM4215, PVC, … others on request | |

| Line size | 1/8 in. to 6 in. (DN 6 to DN 150), … others on request | |

| Process connection | Flanges (ASME, DIN, JIS), Clamps (TC, ISO, DIN), Female Threads (NPT, DIN), Sanitary Threads (DIN 11851), Tube Ends (DIN, ISO, OD), Varivent, … others on request | |

| Process pressure | 10 mbar to 100 bar (0.15 psi to 1450 psi) – higher on request depending on process connection, materials and design | |

| Windows | 1-Pyrex®, 2-Sapphire, 3-Sapphire Biotech | |

| Window gaskets | Silicone (FDA), Viton® (FDA), EPDM (FDA / USP Class VI), Kalrez® 4079, … others on request | |

| Temperature Ratings | ||

| Process temperature | permanent:0 – 100 °C (32 – 212 °F)

peak (15 min/day):0 – 120 °C (32 – 248 °F) |

|

| Process temperature OPTION HT |

permanent:-20 °C – 190 °C (-4 °F – 374 °F)

peak (15 min/day):-20 °C – 210 °C (-4 °F – 410 °F) |

|

| Ambient temperature | operation:0 – 40 °C (32 – 104 °F)

operation:-20 – 40 °C (-4 – 104 °F) with option HT transport:-20 – 70 °C ( -4 – 158 °F) |

|

| Pressure and temperature ratings specified herein may be subject to limitations – see instruction manual. The appropriate choice of material for all wetted parts is the sole responsibility of the user. Data given are subject to changes without prior notice. | ||